Transform Your Space with Premium Polished Concrete Flooring in Bangladesh

Polished Concrete is a high-gloss finish achieved by using special floor polishers fitted with diamond abrasive disks to grind down surfaces to the desired degree of glossiness and smoothness. Falcon Solution Ltd providing the best service for Polished Concrete in Bangladesh as the best applicator as well as a contractor at affordable prices. We are also providing the best service for Epoxy flooring, PU flooring, Polished concrete, Vinyl flooring, Floor Hardener in Bangladesh.

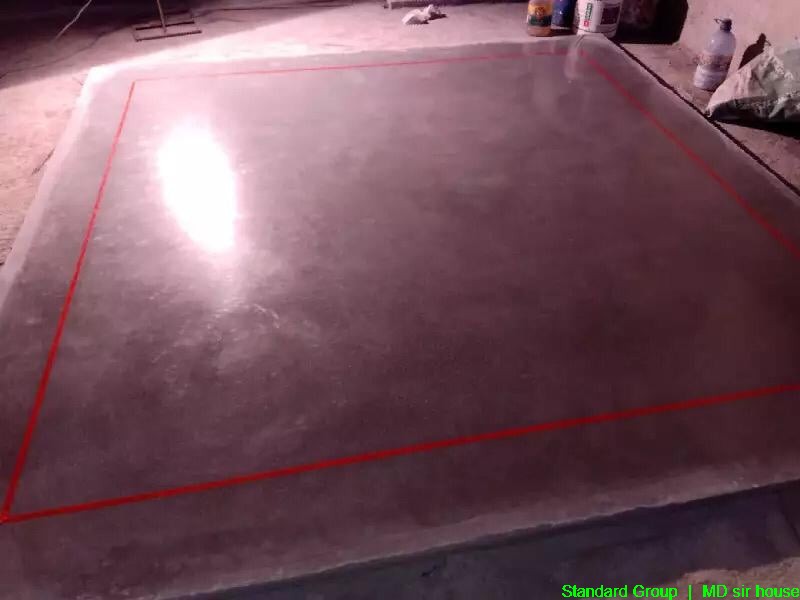

Concrete Polishing enhances the natural beauty of concrete. Through a process of densifying the concrete with impregnate hardeners and grinding with diamond tooling, we can achieve a high gloss floor that is as beautiful as it is durable. The resulting surface is very low-maintenance and can be branded/dappled to replicate the look of polished stone.

Designed for use on old or new concrete in both prestigious commercial or residential projects and intimate residential spaces. Polished concrete in Bangladesh has unlimited design ability to transform ordinary concrete into a limitless palette of color and design.

Concrete has long been known for its stability and cost-saving features. Polished concrete in Bangladesh is a popular alternative to other flooring materials because of three attractive benefits: lower total cost, lower maintenance, and aesthetics.

Apply Polished Concrete in several Surfaces

New Concrete Surfaces: All the need aggregates materials are often as well as once concrete combination and casting. Once we grinding and sprucing the concrete enclosed materials can show and making a nice-looking surface. So, everything that concerning your need end have to be compelled to want to embody ornamental glass, metal or rock in concrete combine.

Existing Concrete Surfaces: If your concrete floor already exists, there are innumerable ways in which to create it distinctive, shiny and glossy yet as colorful. We have a tendency to add color to the surface with dyes or stains. Concrete can absorb the color by small pore and capillaries, permanent color achieves existing concrete and obtain a special look. This could be achieved by multiple color mixtures.

Existing Weak / Rough Concrete: We're applying building material overlay on prime of weak or rough concrete floor surface. These overlays are cement primarily based, self-leveling giving concrete an identical and even look. We have a tendency to might add color full glass or stone for an ornamental trendy end. Building material overlay could be a smart resolution for concrete that needs an excessive amount of repair, has cracks or maybe wants a leveling swish floor end.

Some of the advantages of polished concrete

Concrete sharpening has become wildly widespread recently associated with a sensible reason. It comes with a bunch of advantages that are engaging folks to urge it done. Here are a unit some reasons to think about Polished Concrete for your next project!

Elimination of Dusting from Efflorescence In standard unpolished concrete, small particles of dirt area unit pushed to the surface through associate upward force referred to as fluid mechanics pressure, leading to efflorescence. Efflorescence results in dusting that forces epoxies off of the surface of concrete floors and may create maintenance a pricey priority.

Stain-Resistant By dandifying and protect the surface, polished concrete transforms a porous concrete floor into a tightened floor that's dense enough to repel water, oil, and alternative contaminants, preventing them from penetrating the surface.

Improved Reflectivity and close lighting The reflective properties of an elegant concrete floor will increase the lighting in facilities. Enlarged close lighting can cut back the energy bill yet as look stunning.

Increased Slip Resistance Polished concrete, although quite shiny, doesn't produce a slippery floor. In fact, the advantages of automatically grinding and flattening the ground can increase the constant friction compared to standard concrete. Polished concrete typically exceeds Occupational Safety and Health Administration standards for floors. (ASTM C 1028)

Less Maintenance Most floor systems, as well as tile and lion, need aggressive cleansing to take care of clean surroundings and nice look. Polished concrete surfaces area unit tightly compacted, reducing stains and don't need any waxing or uncovering to take care of the refulgence.

Cost-Effective Polished concrete can cut back energy and maintenance prices considerably through reflectivity and close lighting, reduction in maintenance (such as waxing) and reduced tire wear.

LEED Friendly Polished concrete not solely utilizes existing concrete surfaces, eliminating extra materials like coverings/coatings and moving towards property building, it generally contains no noticeable VOC's, creating it friendly for any USBG LEED project.

Improved condition for recent floors (Mechanical Polish Only) As concrete ages, surface stress, delamination, curled cold joints, and alternative issues will arise. Automatically grinding the ground can take away the highest surface of the recent concrete and sharpening can then strengthen it, increasing its impact and abrasion resistance.

Reduced Tire Wear (Mechanical Polish) The rough, uneven texture of natural concrete causes tires to abrade, adding to their wear. An elegant concrete floor system can level the joints and create the complete surface swish, preventing this abrasion.

No Production/Plant Shutdowns (Mechanical Polish) Dry-Mechanically polished concrete will be placed into service straight off when the method is complete. Because of the cleanliness of the method and also the lack of harmful or venturous chemicals, floors will typically be maintained whereas the plant is full production.

Start Your Polished Concrete Project Today

At Falcon Solution Ltd, we are committed to offering sustainable and eco-friendly solutions for all your flooring needs. Whether you're upgrading your residential or commercial space, our polished concrete floors provide durability, elegance, and long-lasting performance. Let us help you create a stunning and environmentally responsible floor that will stand the test of time.

For a Free Quotation or to discuss your Falcon Solution Ltd. Requirements, Contact us today or Visit Office.

- Resistant to heavy loads

- Antistatic Anti-Corrosive

- Durable, Tough Impervious

- Ensures Complete Satisfaction

- Hygienic Food Grade

- High-Temperature Resistant

- High-Abrasion Resistant

- Impact and Pressure Resistant

- Light Chemicals Resistant

- Long Lasting Economical

- Slip Resistant Easy to Clean

- Weather Resistant

- Hospitals & Pharmaceuticals

- Beverages & Food Processing

- Engineering & Chemicals

- Hotel, Kitchen & Cafeteri

- Garments, Textile & Spinning

- Knitting & Dyeing

- Warehouses & Stores

- Salt & Acid Areas

- Any Kinds of Heavy Load Areas

- Any Kinds of Industries